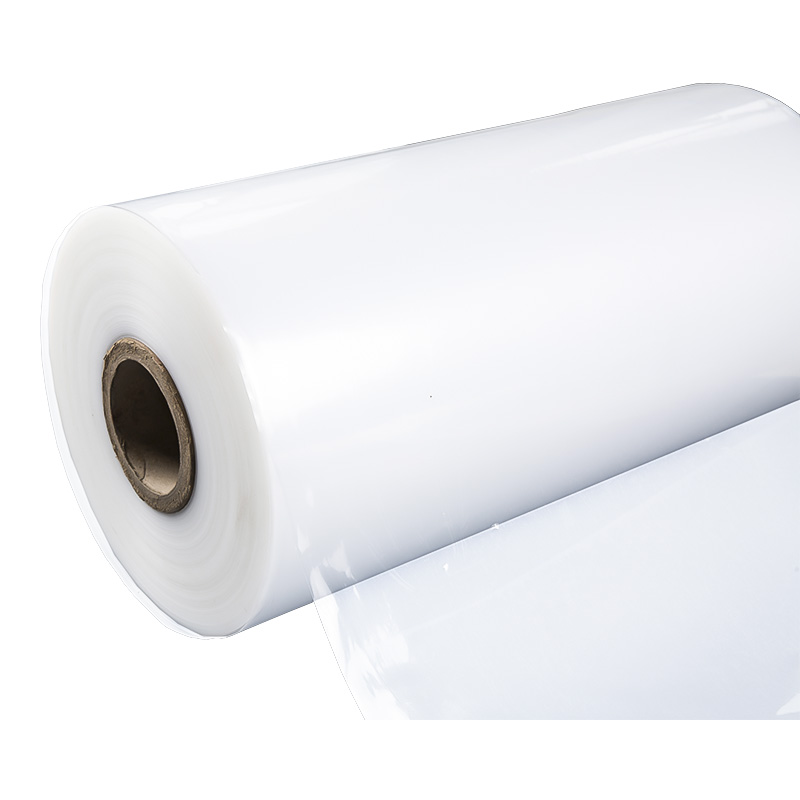

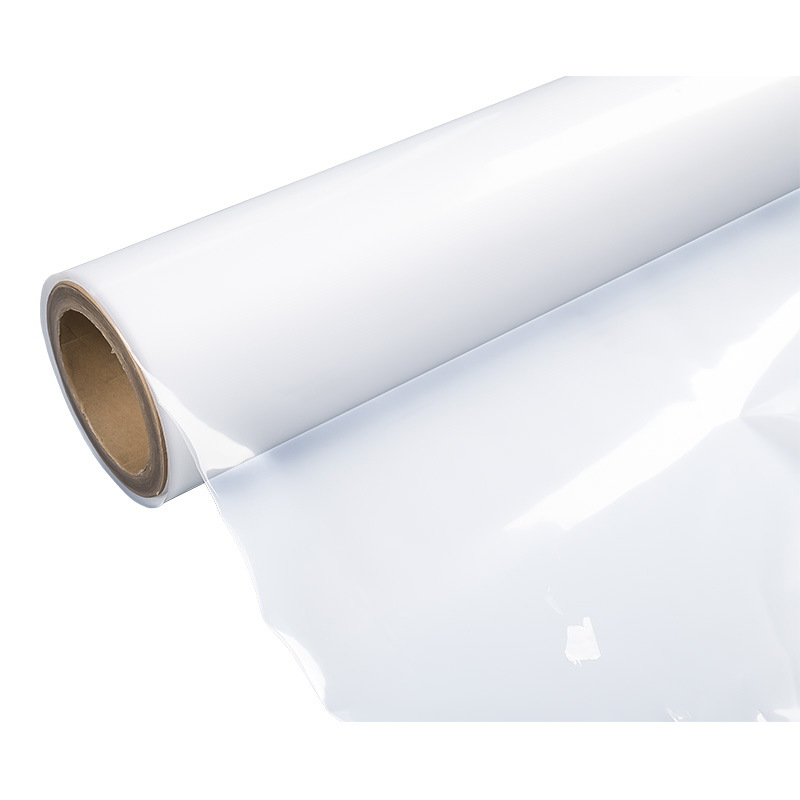

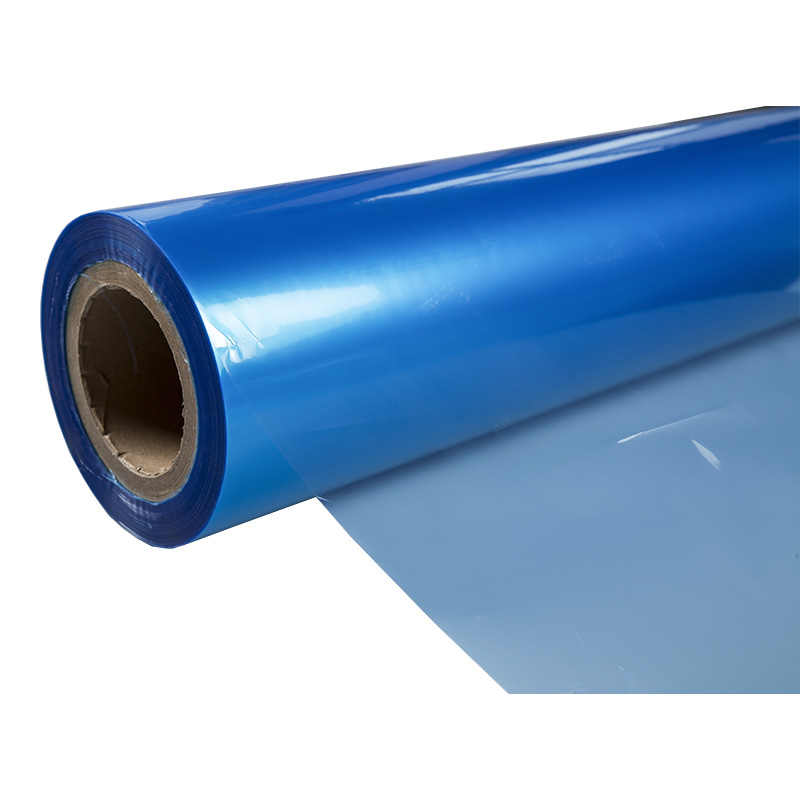

The application of Custom Antistatic film in the electronics industry is crucial. As a key material to protect electronic components from electrostatic damage, it is widely used in semiconductor manufacturing, flat panel display, circuit board production and other sub-sectors.

1. Semiconductor Manufacturing

In the semiconductor manufacturing process, antistatic film plays a vital role. Semiconductor chips are the heart of electronic devices, and their manufacturing process requires extremely high precision and cleanliness. Electrostatic discharge (ESD) is one of the common threats in semiconductor manufacturing, which may cause damage to the internal circuit of the chip or performance degradation. Therefore, in the semiconductor manufacturing process, the use of antistatic film can effectively prevent static electricity from damaging the chip.

Antistatic film is usually used in multiple links in wafer manufacturing, such as photolithography, etching, ion implantation, etc. In these processes, the surface of the wafer needs to maintain extremely high cleanliness and static-free state. Antistatic film can provide a stable electrostatic protection layer to prevent the wafer from being disturbed and damaged by static electricity during the manufacturing process. In addition, during the storage and transportation of wafers, antistatic film can also provide effective protection to ensure the integrity and reliability of the wafer.

2. Flat Panel Display

The flat panel display field is another important application market for antistatic film. Flat panel display technologies include liquid crystal display (LCD), organic light-emitting diode display (OLED), micro-light-emitting diode display (Micro-LED), etc. In the manufacturing process of these display technologies, antistatic film is widely used to protect the display panel from damage by electrostatic discharge.

In the manufacturing process of flat panel display, the display panel needs to go through multiple process steps such as exposure, etching and assembly. In these steps, static electricity may damage the display panel, resulting in degradation or failure of display quality. Therefore, the use of antistatic film can effectively prevent static electricity from damaging the display panel and improve the stability and consistency of display quality. In addition, antistatic film can also prevent the adhesion of dust and impurities, and improve the cleanliness and reliability of the display panel.

3. Circuit board production

Antistatic film also plays an important role in the production process of circuit boards. Circuit boards are bridges connecting various components in electronic devices, and their manufacturing process needs to ensure the integrity and reliability of the circuit boards. In the manufacturing process of circuit boards, electrostatic discharge may damage the components and lines on the circuit boards, resulting in failure or performance degradation of the circuit boards.

In the manufacturing and assembly process of circuit boards, the use of antistatic film can effectively prevent static electricity from damaging the circuit boards. Antistatic film can provide a stable electrostatic protection layer to prevent the circuit board from being disturbed and damaged by static electricity during the manufacturing and assembly process. In addition, antistatic film can also prevent the adhesion of dust and impurities, and improve the cleanliness and reliability of the circuit board.

4. Other applications

In addition to the above fields, Antistatic film is also widely used in other fields of the electronics industry. For example, in the packaging and transportation of electronic components, the use of antistatic film can effectively prevent static electricity from damaging the components; in the repair and maintenance of electronic equipment, the use of antistatic film can prevent static electricity from interfering with and damaging the internal circuits of the equipment.

Custom Antistatic film is widely used and important in the electronics industry. As a key material for protecting electronic components from static electricity damage, it plays an irreplaceable role in many fields such as semiconductor manufacturing, flat panel displays, and circuit board production. With the continuous development of the electronics industry and the continuous advancement of technology, the application prospects of antistatic film will be broader.

+86 139-6715-0258

+86 139-6715-0258

Monday to Friday 8 am. to 6 pm.

Monday to Friday 8 am. to 6 pm.

English

English 中文简体

中文简体