1. Basic Properties of PP Film

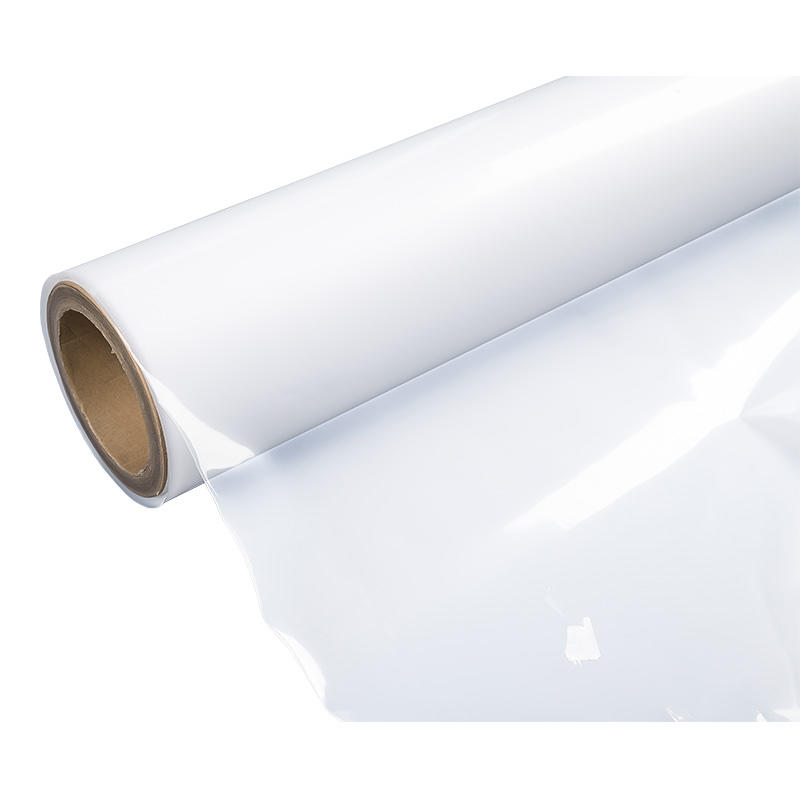

Polypropylene film has a series of unique physical properties, making it an ideal packaging material. Its main characteristics include:

High strength and toughness: PP film has high tensile strength and tear resistance. Even under high tension, it can maintain good shape stability and is not easy to break.

Good transparency: Polypropylene film has excellent transparency, especially PP film in the form of film, which can provide clear visual effects and is suitable for display packaging.

High temperature resistance: Compared with other plastic materials, polypropylene has a higher melting point (about 160°C) and can maintain morphological stability in a certain high temperature environment, which is suitable for packaging needs that require high temperature resistance.

Excellent chemical stability: PP film has good corrosion resistance to most acids, alkalis and solvents, and is not easily attacked by chemicals, which makes it suitable for some packaging environments with high requirements for chemical stability.

Low moisture permeability: PP film has relatively low water vapor permeability, which is essential for the fresh-keeping packaging of certain foods and chemicals.

2. Application of PP Film in Custom Paper Plastic Bag Film

Polypropylene film is widely used in custom paper plastic bag film, especially in situations where durability, environmental protection and high transparency are required. The following are some specific applications of PP film in this field:

Food packaging: Polypropylene film is often used to package various foods, especially those products that require a longer shelf life, such as cooked food, dry goods, quick-frozen food, etc. Because PP film has good moisture resistance and gas barrier properties, it can effectively extend the shelf life of food and reduce external environmental pollution.

Bagged snacks: PP film is often used in the packaging of snacks such as potato chips, biscuits, and nuts, which can not only ensure the firmness of the packaging bag, but also show the clear appearance of the product.

Quickly frozen food packaging: Quickly frozen foods such as frozen vegetables and meat are also often packaged in PP film because of its good low temperature resistance and are not easy to become brittle or cracked in a low temperature environment.

Daily consumer goods packaging: Toilet paper, cosmetics, detergents and other household daily commodities, using PP film packaging can improve the market display of the product and ensure its quality. Due to the high transparency of PP film, consumers can clearly see the appearance of the product and increase their confidence in purchasing.

Industrial packaging: PP film is often used to package various industrial products, especially for some commodities that require strength and tear resistance, such as building materials, electronic products, etc. The high tensile strength of polypropylene film enables it to effectively protect the goods from damage during transportation.

Pharmaceutical product packaging: For the packaging of some medicines and medical devices, PP film can ensure that the products remain clean and safe during transportation and storage due to its excellent chemical stability and anti-pollution properties.

3. Advantages of PP film in customized paper-plastic bag film

As a material for customized paper-plastic bag film, polypropylene film has shown its unique advantages in many aspects:

High strength and durability: PP film has excellent tear resistance and tensile resistance, and is suitable for making large packaging bags or packaging of commodities that need to be frequently handled. Compared with traditional plastic bags, PP film can provide stronger protection and reduce losses caused by packaging damage.

Excellent transparency and display effect: Due to the high transparency of PP film, it can clearly display the products inside the package. For retail products, this transparent effect can attract customers' attention and increase product exposure and sales.

Lightweight and low cost: PP film has a relatively low production cost and is lightweight, which helps reduce transportation costs. For bulk commodities and large-scale production needs, polypropylene film is a very economical choice.

Better environmental protection: Although PP film itself is a plastic product, it has good recyclability and can be reused through appropriate treatment and recycling processes. PP film has less burden on the environment than some non-degradable materials.

Moisture and water resistance: PP film has low water vapor permeability and has certain moisture and water resistance functions, which can protect products from humid environments and is especially suitable for packaging items that are sensitive to humidity.

4. Disadvantages and limitations of PP film

Although the application of PP film in customized paper-plastic bag film has many advantages, it also has some disadvantages and limitations:

Lower gas barrier property: Although PP film has good barrier properties to moisture, its gas barrier properties (such as oxygen and carbon dioxide) are relatively weak. It may not be suitable for products with high freshness requirements that need to be isolated from external gases for a long time, such as certain specific food packaging.

Brittleness: Although PP film has high strength, it may become brittle at low temperatures or under extreme external forces, especially when used in cold environments, and is prone to cracking or damage.

Non-degradability: Although PP film is recyclable, it is not a biodegradable material. Accumulation in the environment will cause certain pressure on the ecology, especially when used in large quantities.

+86 139-6715-0258

+86 139-6715-0258

Monday to Friday 8 am. to 6 pm.

Monday to Friday 8 am. to 6 pm.

English

English 中文简体

中文简体