In order to ensure the quality and service life of medical device packaging film rolls, they should be stored in a light-proof environment and avoid direct sunlight. Here are some suggestions to help achieve this goal:

1. Choose a suitable storage environment: When storing medical device packaging film rolls, you should choose an environment with weak light, moderate temperature, and suitable humidity. Avoid placing it in direct sunlight, such as near a window or on a balcony. In addition, it is necessary to ensure that the storage environment is dust-free and pollution-free to avoid affecting the hygienic performance of the packaging film roll.

2. Use blackout curtains or sun visors: In the room where medical device packaging film rolls are stored, blackout curtains or sun visors can be installed to block the entry of ultraviolet rays. These devices can effectively reduce the direct exposure of sunlight to packaging film rolls, thereby reducing the impact of ultraviolet rays on them.

3. Regularly inspect and replace packaging film rolls: In order to ensure that medical device packaging film rolls are always in good condition, they should be inspected regularly. Once problems such as color fading, performance degradation or damage are found, new packaging film rolls should be replaced in time. At the same time, used packaging film rolls should also be properly disposed of to avoid environmental pollution.

4. Use anti-UV materials: When producing medical device packaging film rolls, you can consider using anti-UV materials. These materials can effectively resist UV damage and extend the service life of packaging film rolls. At the same time, anti-UV materials can also improve the protective performance of packaging film rolls and ensure the safety and effectiveness of medical devices.

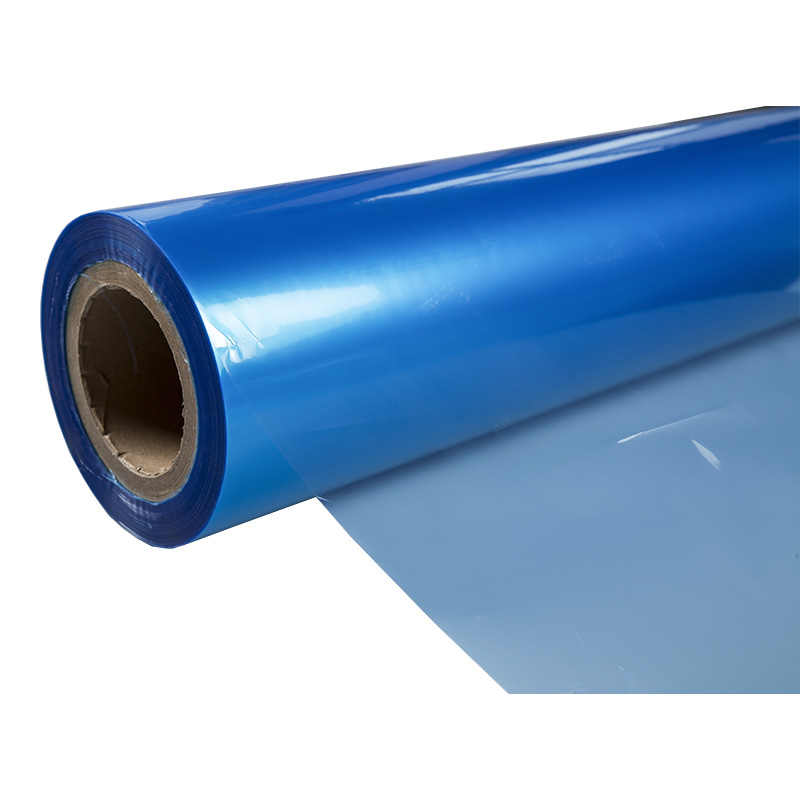

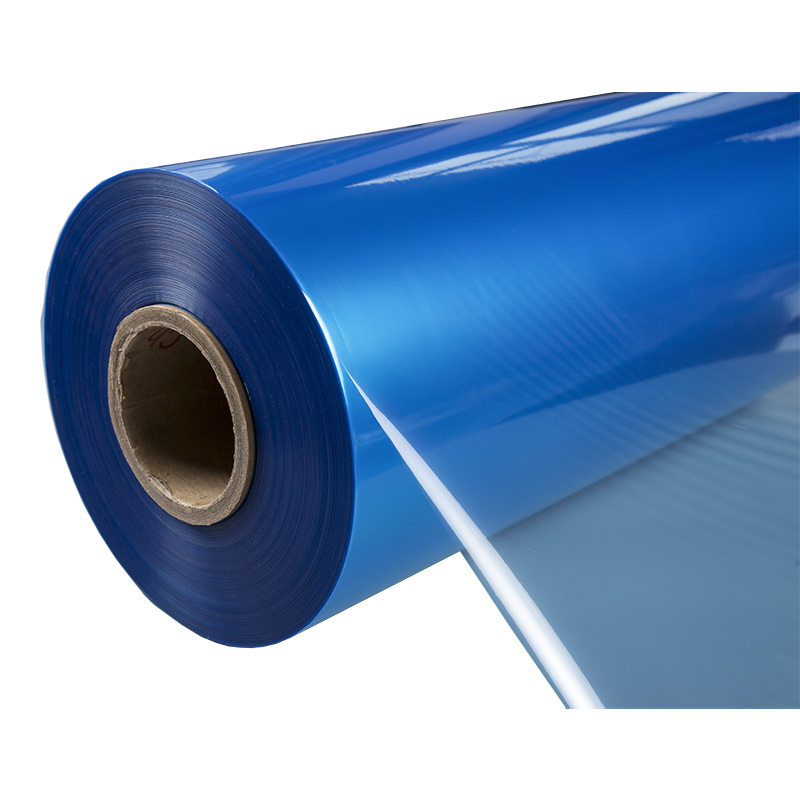

The impact of long-term ultraviolet irradiation on blue medical device packaging film rolls is serious. In order to ensure the quality and service life of packaging film rolls, effective measures should be taken, such as choosing a suitable storage environment, using blackout curtains or sun visors, regularly inspecting and replacing packaging film rolls, using anti-UV materials, etc., to reduce the impact of ultraviolet rays on packaging films volume impact.

+86 139-6715-0258

+86 139-6715-0258

Monday to Friday 8 am. to 6 pm.

Monday to Friday 8 am. to 6 pm.

English

English 中文简体

中文简体