1. The impact of oxidation reaction on frozen food

Oxidation reaction is a factor that cannot be ignored in the food spoilage process. It involves the chemical reaction between unsaturated fatty acids, vitamins, pigments and other components in food and oxygen, resulting in food color darkening, flavor loss, nutritional value reduction, and even the production of bad odors and harmful substances. Under freezing conditions, although low temperatures significantly slow down the rate of most chemical reactions, oxidation reactions do not stop completely. Especially during the process of thawing and refreezing food, the oxidation rate may increase significantly due to temperature fluctuations, causing irreversible damage to food quality.

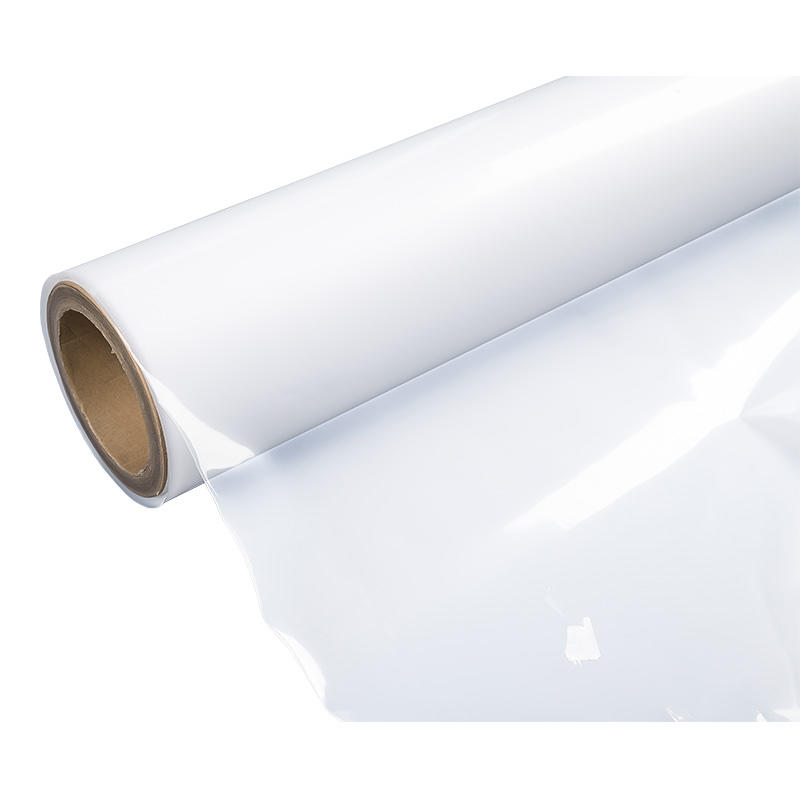

2. The mechanism of action of frozen packaging film

Through its unique material and structural design, Frozen Packaging Film effectively blocks the contact between oxygen and food, thereby inhibiting the occurrence of oxidation reactions. These membranes typically contain multiple layers, each optimized for specific properties such as oxygen barrier, moisture retention, puncture resistance, etc.

High oxygen barrier layer: This is the most critical layer in freezer packaging films, usually made of polymer materials such as polyvinyl alcohol (PVOH), ethylene-vinyl alcohol copolymer (EVOH) or nylon (Nylon). These materials have extremely low oxygen transmission rates and can effectively block external oxygen from entering the interior of the packaging, thereby slowing down the oxidation process of food.

Multi-layer co-extrusion technology: In order to improve the overall performance of packaging films, multi-layer co-extrusion technology is usually used. This technology stacks films of different materials together and forms a single-structure composite film through hot pressing or bonding. Multilayer coextruded films not only have excellent oxygen barrier properties, but can also adjust other properties according to needs, such as mechanical strength, heat sealability, transparency, etc.

Active packaging technology: In some high-end applications, frozen packaging film also incorporates active packaging technology, that is, adding antioxidants, antibacterial agents and other additives to packaging materials. These additives can actively absorb or neutralize harmful substances such as oxygen and free radicals in the packaging, further extending the shelf life of food.

3. Application and effect in practice

The application effect of frozen packaging film in preventing oxidation reaction is remarkable. Take meat products as an example. Frozen meat without special packaging will become darker due to oxidation after being stored for a long time, and the oxidation of fat will produce odor. By using high-oxygen-barrier frozen packaging films, the color of meat products can be maintained, the degree of fat oxidation is significantly reduced, and the taste and nutritional value are closer to fresh meat.

Frozen packaging film is also widely used in seafood, fruits and vegetables, baked goods and other fields. For seafood, the high-oxygen barrier film can prevent the fishy smell from spreading and keep the seafood delicious; for fruits and vegetables, the low-oxygen environment in the film helps slow down respiration and enzymatic browning, extending the shelf life; for baked goods, It can effectively prevent oil oxidation and flavor loss.

4. Future development trends

As consumers' requirements for food safety and quality continue to increase, and the food industry explores sustainable packaging materials, the development of frozen packaging films shows the following trends:

Bio-based and degradable materials: In order to reduce environmental pollution, more and more frozen packaging films are beginning to use bio-based or degradable materials, such as PLA (polylactic acid), PHA (polyhydroxyalkanoate), etc. Not only do these materials have good oxygen barrier properties, they also break down quickly in the natural environment.

Intelligent packaging: Combining advanced technologies such as the Internet of Things and sensors, develop an intelligent packaging system that can monitor oxygen concentration, temperature and other parameters in the package in real time to provide more accurate protection for food.

Multi-functional integration: In the future, frozen packaging films will not only be limited to oxygen barrier, but will also integrate more functions, such as antibacterial, anti-fog, easy to open, etc., to meet the special needs of different foods.

+86 139-6715-0258

+86 139-6715-0258

Monday to Friday 8 am. to 6 pm.

Monday to Friday 8 am. to 6 pm.

English

English 中文简体

中文简体