Choosing the right frozen food packaging film to meet the needs of different products requires comprehensive consideration of multiple factors. Here are some key steps and points:

1. Understand product characteristics

First, it is necessary to clarify the specific characteristics of frozen food, including its moisture content, fat content, shape, shelf life requirements, and storage and transportation conditions. These characteristics will directly affect the choice of packaging film.

2. Consider the performance of packaging film

Low temperature resistance: Frozen food packaging film must have good low temperature resistance to withstand the low temperature environment during the freezing process without cracking or deformation. Different packaging materials perform differently at low temperatures, such as polyethylene (PE) materials have good low temperature resistance.

Barrier properties: The packaging film should have good barrier properties to prevent oxygen, moisture and odor from eroding food. High barrier packaging film can effectively extend the shelf life of food and maintain the freshness and taste of food.

Mechanical strength: The packaging film should have a certain mechanical strength to withstand external forces such as extrusion and collision during transportation to prevent packaging damage from causing food contamination and waste.

Sealing: Good sealing performance is the key to maintaining food quality and safety. The packaging film should be able to effectively prevent air and moisture from entering the packaging bag to ensure the stability of food quality during storage and transportation.

3. Choose the right material according to product requirements

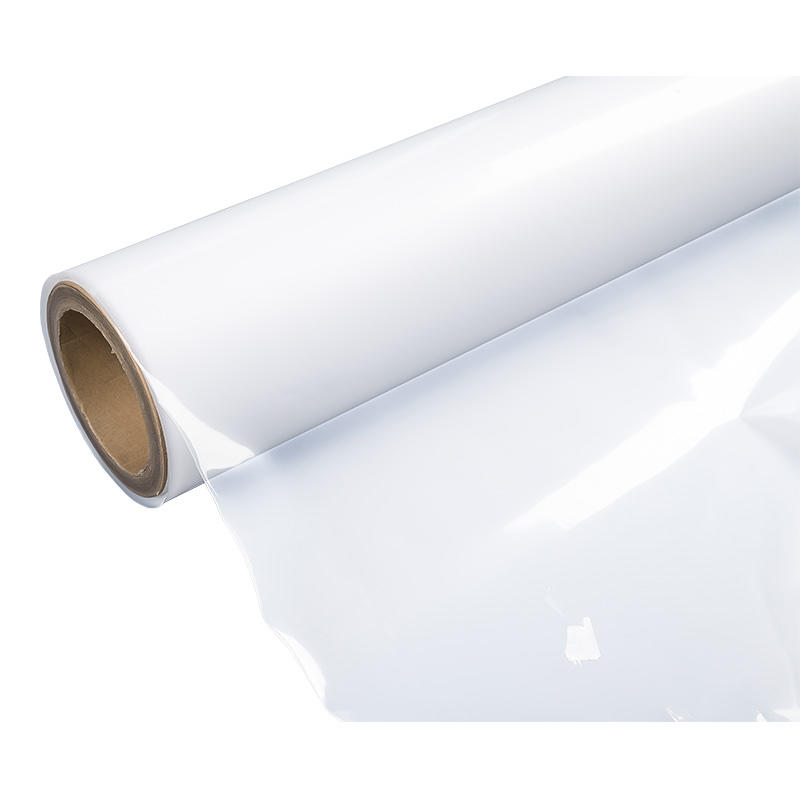

Single material packaging film: such as polyethylene (PE) film, suitable for a variety of frozen foods, with excellent low temperature resistance and heat sealing performance. But its barrier performance is relatively limited, suitable for products with low barrier requirements.

Composite material packaging film: such as PET/PE, NY/PE and other composite material structure packaging film, combines the advantages of multiple materials, has higher barrier performance and mechanical strength. These materials are suitable for high-end or long-term storage of frozen foods.

Aluminum foil packaging film: Aluminum foil packaging film has excellent thermal insulation and barrier properties, which can effectively maintain the freshness and taste of food. But its cost is relatively high, suitable for high-value or special requirements of frozen foods.

4. Consider environmental protection and sustainability

When choosing packaging film, you should also pay attention to its environmental performance and sustainability. Give priority to degradable or recyclable materials to reduce the burden on the environment.

5. Refer to industry standards and regulations

Ensure that the selected packaging film meets relevant industry standards and regulatory requirements to ensure product safety and compliance.

Choosing a suitable frozen food packaging film requires comprehensive consideration of product characteristics, packaging film performance, material cost, environmental protection requirements, and industry standards. By scientifically and rationally selecting and using packaging films, the quality and safety of frozen foods during storage and transportation can be ensured.

+86 139-6715-0258

+86 139-6715-0258

Monday to Friday 8 am. to 6 pm.

Monday to Friday 8 am. to 6 pm.

English

English 中文简体

中文简体