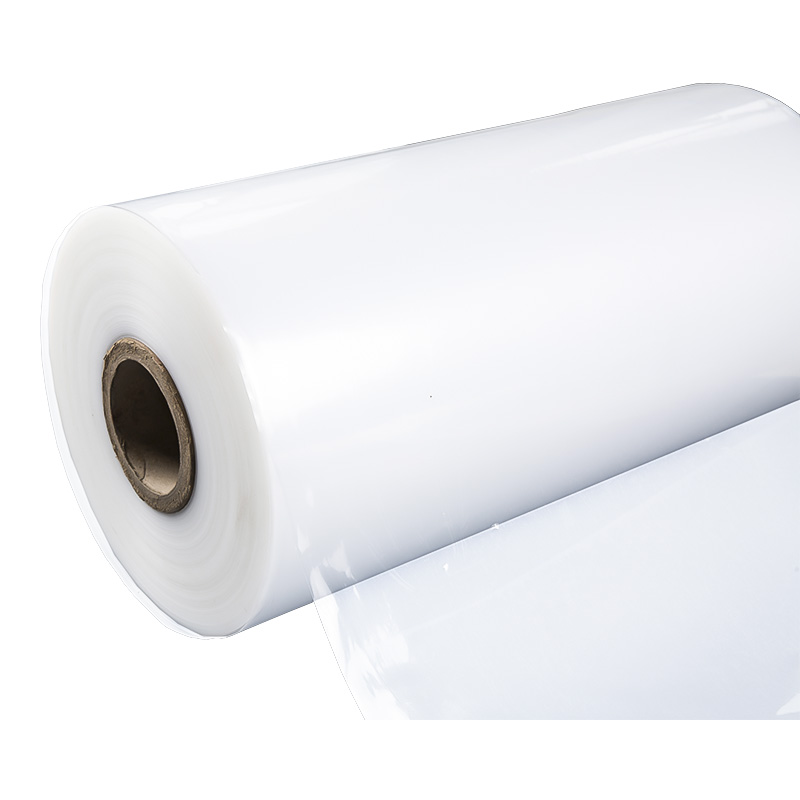

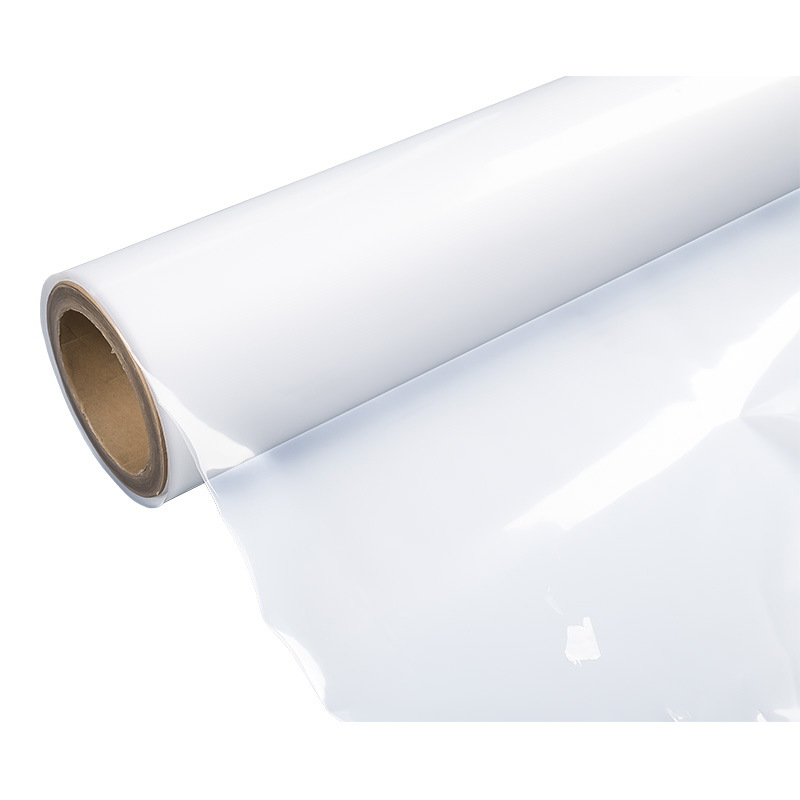

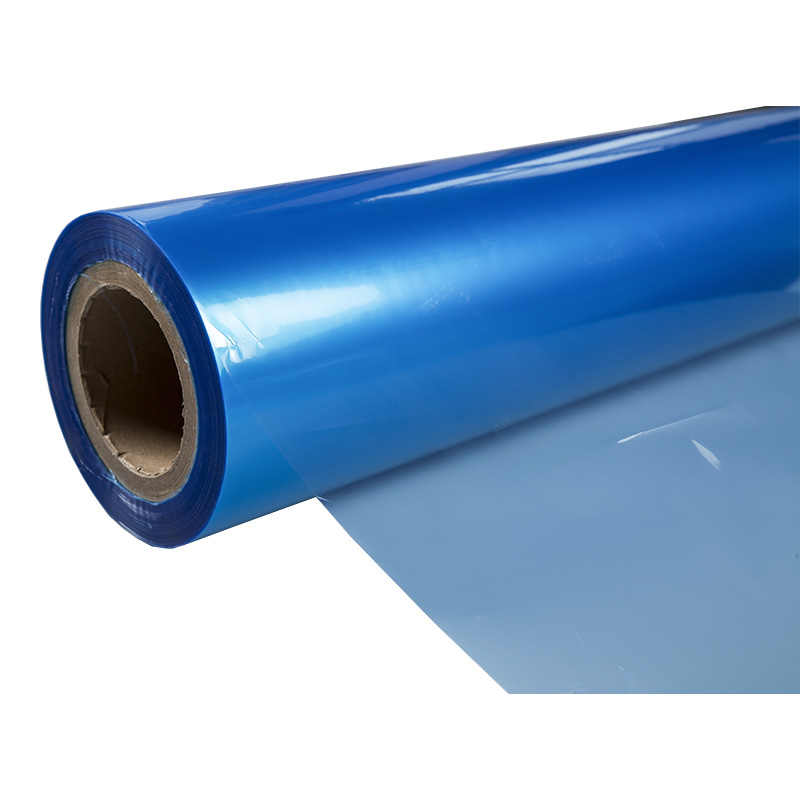

In the wave of modern industrial and technological development, the problem of static electricity has become a difficult problem that cannot be ignored. Static electricity may not only cause equipment failure, but also pose a threat to product quality and personnel safety. In order to deal with this problem, Antistatic Film came into being, and with its antistatic performance, it plays an indispensable role in many industries.

1. Electronics industry: key protective layer

In the electronics industry, static electricity is particularly harmful to electronic components. Even a tiny electrostatic discharge may cause damage to sensitive components such as integrated circuits and transistors. Therefore, in the production, transportation and storage of electronic products, using Antistatic Film as a packaging material or protective film can effectively avoid static electricity from damaging the product. According to statistics, after using Antistatic Film packaging, the damage rate of electronic components has been reduced by nearly 50%, greatly improving the reliability and stability of the product.

2. Packaging industry: ensuring product quality

In the packaging industry, Antistatic Film also plays an important role. In food packaging, Antistatic Film can effectively prevent food particles from adhering to the packaging due to static electricity, maintaining the hygiene and quality of food. At the same time, it can also prevent adhesion between packaging materials and improve the ease of use and aesthetics of packaging. For electronic products, static electricity is a serious threat. As a packaging material for electronic products, Antistatic Film can effectively prevent static electricity from damaging electronic products and ensure the stability and reliability of products. In pharmaceutical packaging, Antistatic Film can prevent pharmaceutical particles from adhering to the packaging due to static electricity, maintaining the purity and effectiveness of the medicine. At the same time, it can also prevent adhesion between packaging materials and improve the sealing and safety of packaging.

3. Medical industry: ensuring patient safety

In the medical industry, static electricity may also cause damage to surgical instruments, medical equipment, etc., thereby affecting medical quality and patient safety. The application of Antistatic Film provides an effective means of static electricity protection for the medical industry. For example, in the packaging of surgical instruments, the use of Antistatic Film can prevent the instruments from being damaged or contaminated by static electricity; in the maintenance of medical equipment, Antistatic Film can also be used as a protective cover to prevent static electricity from damaging the equipment.

4. Printing industry: improving printing quality

In the printing industry, static electricity problems should not be ignored. Static electricity may cause problems such as paper adhesion and uneven ink distribution, affecting printing quality. As an auxiliary material in the printing process, Antistatic Film can effectively eliminate static electricity and ensure the smooth progress of the printing process. At the same time, Antistatic Film can also be used as a protective film for printed materials to prevent them from being damaged by static electricity during storage and transportation.

V. Other industries: broad application prospects

In addition to the above industries, Antistatic Film is also widely used in textiles, chemicals, aerospace and other fields. For example, in the textile industry, Antistatic Film can be used to make antistatic clothing and fabrics; in the chemical industry, Antistatic Film can be used as an electrostatic protection material; in the aerospace field, Antistatic Film can be used to protect sensitive equipment and instruments from static interference.

+86 139-6715-0258

+86 139-6715-0258

Monday to Friday 8 am. to 6 pm.

Monday to Friday 8 am. to 6 pm.

English

English 中文简体

中文简体