1. The importance of thermal insulation performance

In low-temperature environments, heat conduction is often the main factor causing energy loss. Due to the continuous influence of external low temperatures, the limitations of many traditional materials in isolation capabilities make it impossible to maintain a stable internal environment, resulting in temperature fluctuations. Temperature instability not only affects the normal operation of the system, but also leads to energy waste and unnecessary operating costs. Therefore, improving the thermal insulation performance of materials can not only improve the work efficiency of the system, but also greatly reduce energy waste, ensuring that the equipment or system can operate continuously and efficiently in low-temperature environments.

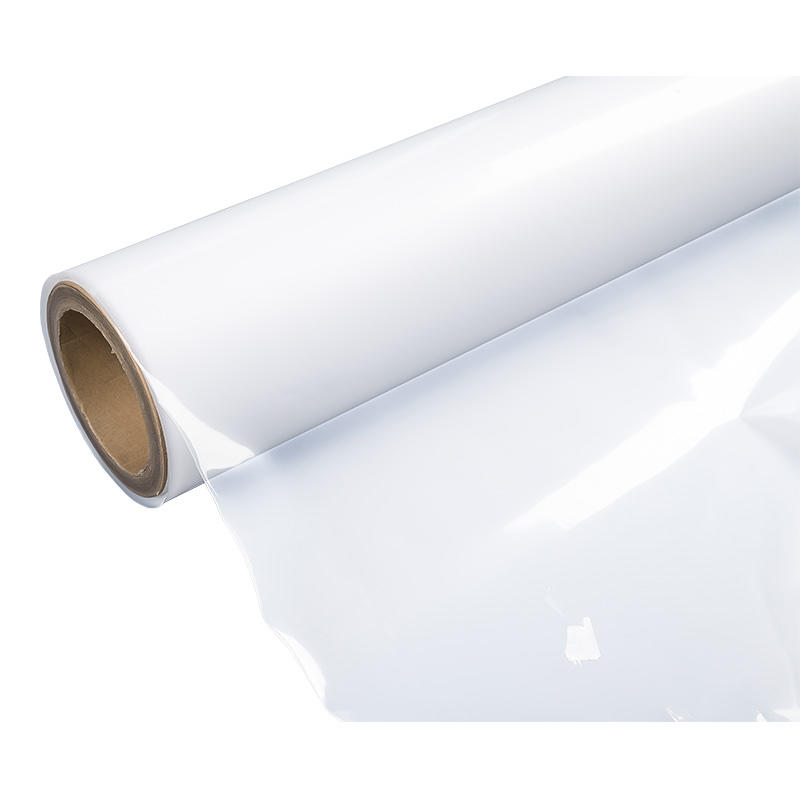

For many devices that require high temperature control, it is crucial to maintain a stable internal temperature. Whether it is cold chain transportation, low-temperature storage, or low-temperature laboratories, the requirements for thermal isolation are very strict. Traditional materials often cannot meet this demand, and Ultra-low temperature composite membrane, with its unique composite material structure, can effectively isolate the influence of external low temperatures, thereby ensuring the stability of the internal environment and reducing the impact of temperature fluctuations on system operation.

2. Excellent thermal insulation performance of Ultra-low temperature composite membrane

The thermal insulation performance of Ultra-low temperature composite membrane comes from its precisely designed composite structure. Compared with traditional materials, this material performs better in low-temperature environments. First, the multi-layer structure of the composite membrane effectively blocks the conduction of external low temperature and forms an efficient thermal isolation barrier. Secondly, the unique properties of this composite membrane material enable it to provide higher thermal isolation effects without sacrificing material strength and toughness.

This feature can significantly improve energy utilization efficiency in applications in low-temperature environments. Due to the thermal isolation effect of the ultra-low temperature composite membrane, it can effectively reduce the leakage of heat or the intrusion of external low temperature, ensuring the stability of the internal temperature of the system. Compared with traditional single materials, the thermal isolation of the ultra-low temperature composite membrane is more prominent and can better cope with the severe challenges in low-temperature environments.

3. Reduce energy loss and improve work efficiency

In low-temperature environments, temperature fluctuations not only affect the normal operation of the system, but also lead to additional energy consumption. Traditional materials often need to maintain the stability of the internal temperature through continuous heating or cooling, which not only increases energy consumption, but also increases the operating cost of the equipment. The efficient thermal isolation performance of the Ultra-low temperature composite membrane can reduce this energy waste and reduce the energy consumption of the equipment. By effectively isolating the influence of external low temperature, the ultra-low temperature composite membrane can help the system maintain a constant temperature, thereby avoiding the need for frequent temperature adjustment.

In addition, as the world's attention to energy efficiency and environmental protection continues to increase, all walks of life are actively seeking solutions to reduce energy loss and carbon emissions. The thermal isolation performance of Ultra-low temperature composite membrane provides an efficient energy-saving option for various industries. Its excellent performance can not only reduce energy consumption, but also reduce the risk of equipment failure caused by temperature fluctuations, thereby improving the stability and reliability of the system.

4. Improve the operational stability of the system

Temperature fluctuations in low-temperature environments not only affect the efficiency of energy utilization, but may also have a negative impact on the stability of the system. Traditional materials are often unable to effectively maintain a constant temperature, resulting in instability in system operation. Ultra-low temperature composite membrane effectively reduces the impact of external low temperature on the system through its excellent thermal isolation properties, ensuring the long-term stable operation of equipment and systems. By reducing the interference of external temperature changes on the internal environment, ultra-low temperature composite membranes can help various low-temperature applications to operate stably in complex environments and improve the overall efficiency of the system.

5. Wide application and broad prospects

With the continuous advancement of science and technology, Ultra-low temperature composite membrane, as a new type of high-performance material, is showing its unique advantages in more and more fields. Whether in low-temperature storage, transportation, or equipment operation in extreme climates, the thermal insulation performance of ultra-low temperature composite films will play a vital role. Its wide application prospects will surely bring significant energy-saving and environmental benefits in multiple industries.

-

+86 139-6715-0258

+86 139-6715-0258 -

+86 135-6714-7662

+86 135-6714-7662 -

Monday to Friday 8 am. to 6 pm.

Monday to Friday 8 am. to 6 pm.

Inquiry

English

English 中文简体

中文简体